Technical advantages

High vacuum degree

Low leakage rate

High safety

Rigorous and complete, slot valve/process module/robot,

Hardware interlock design,

Benchmarking against international first-tier brands,

Through SemiS2 safety certification specifications and parameters.

Multifunctional customization

Supports 100/150/200/300mm wafer transmission function,

Customizes software and functions according to client requirements.

After-sales service

Local technical and service teams with quick response.

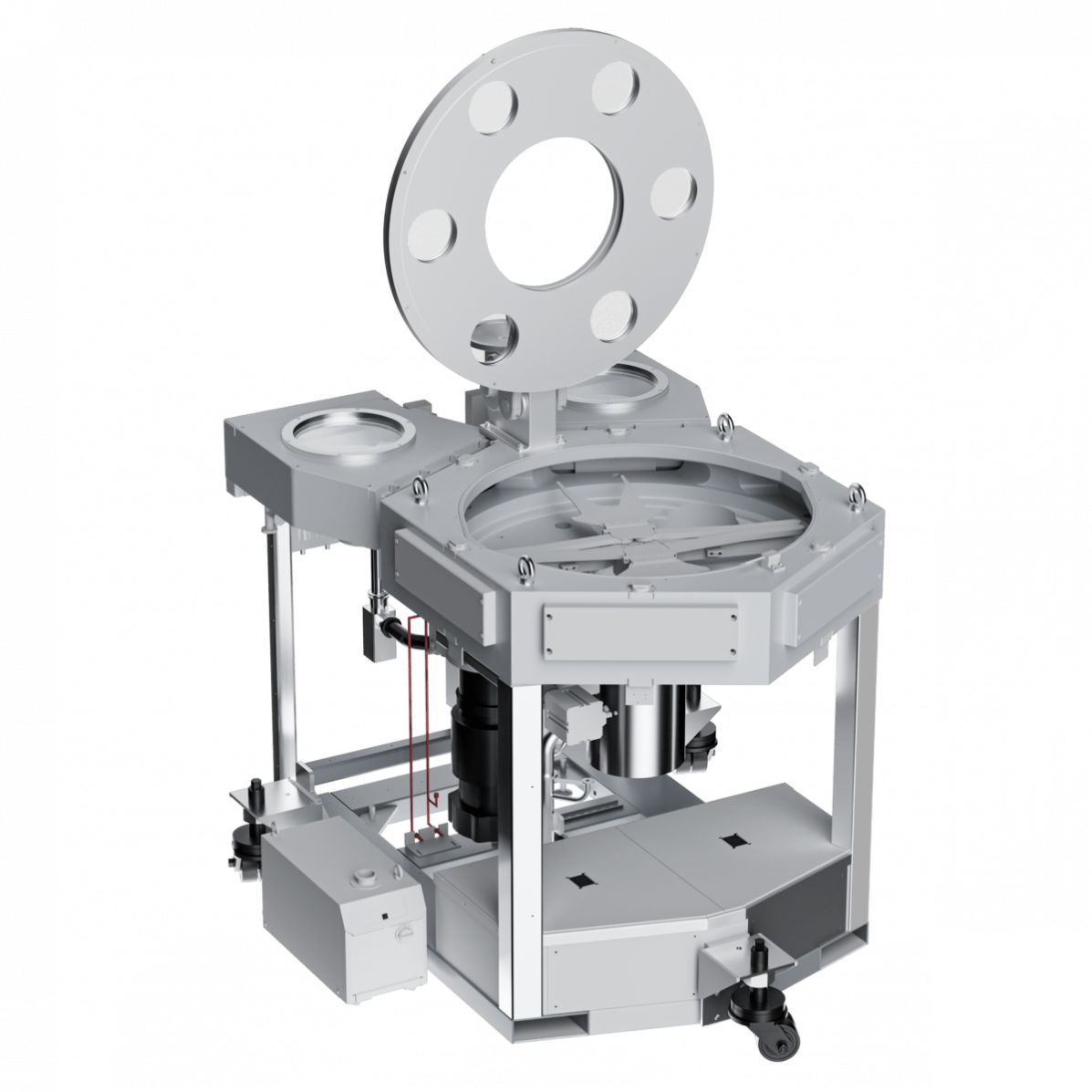

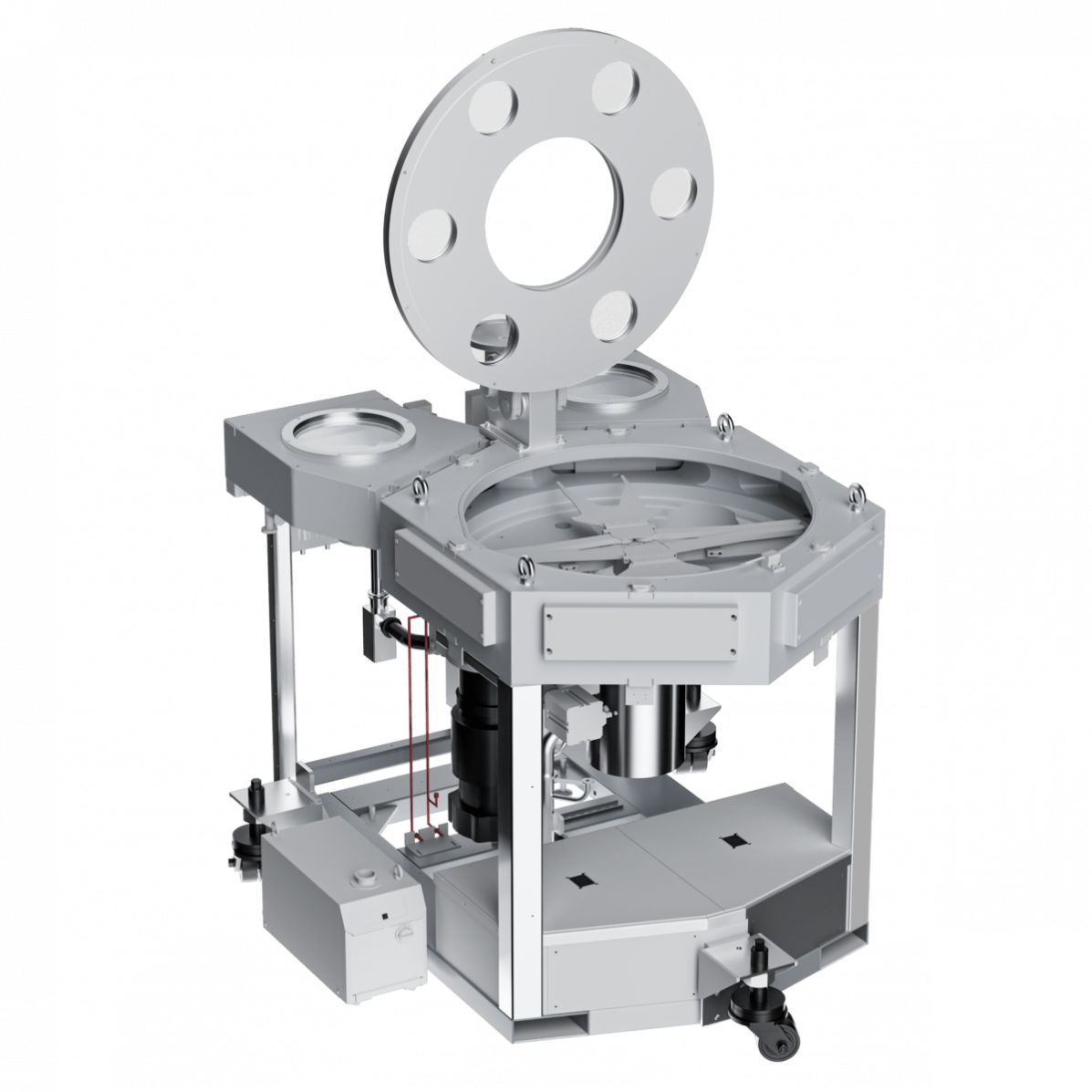

VTM300-HH600

VTM300-HH600

Product Image

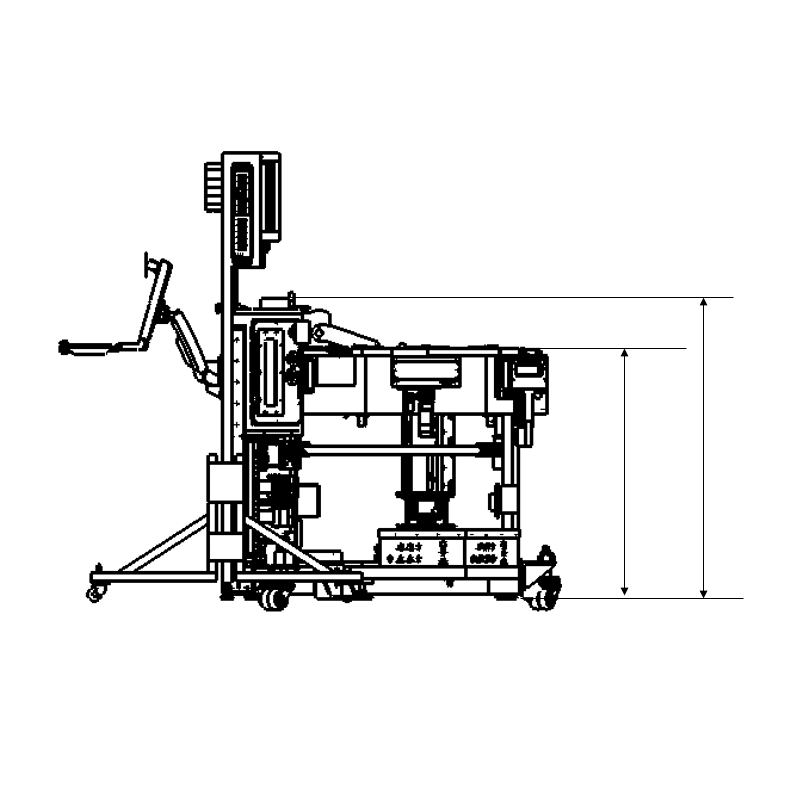

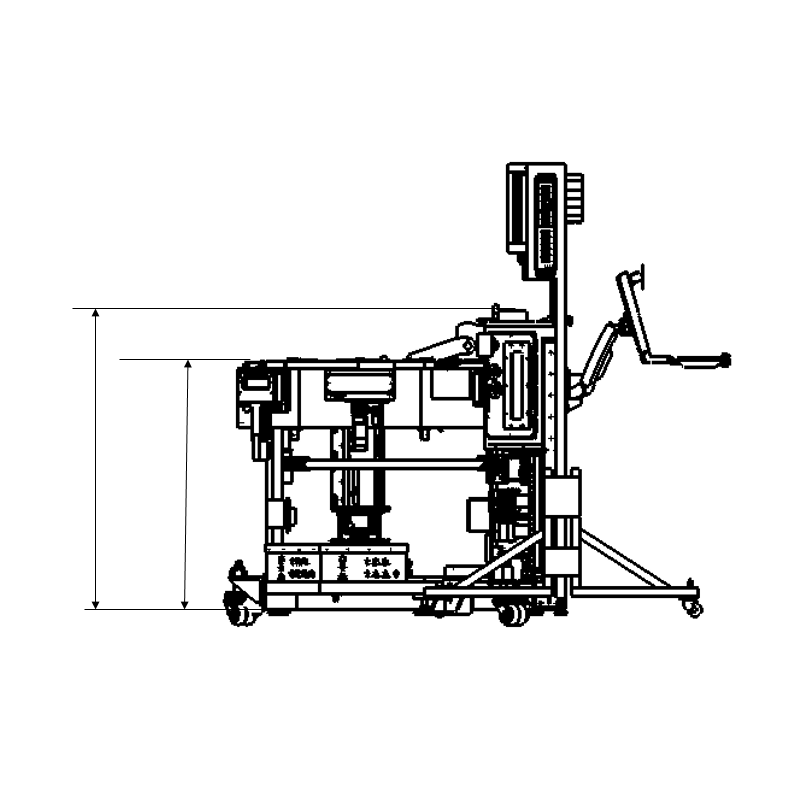

VTM Drawing

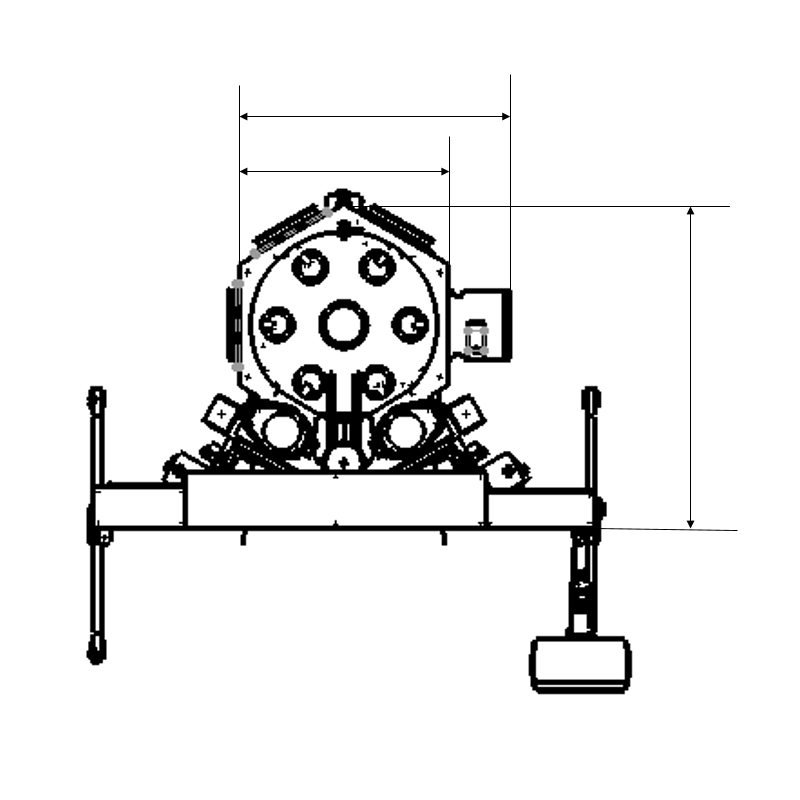

Left view

Right view

Top view

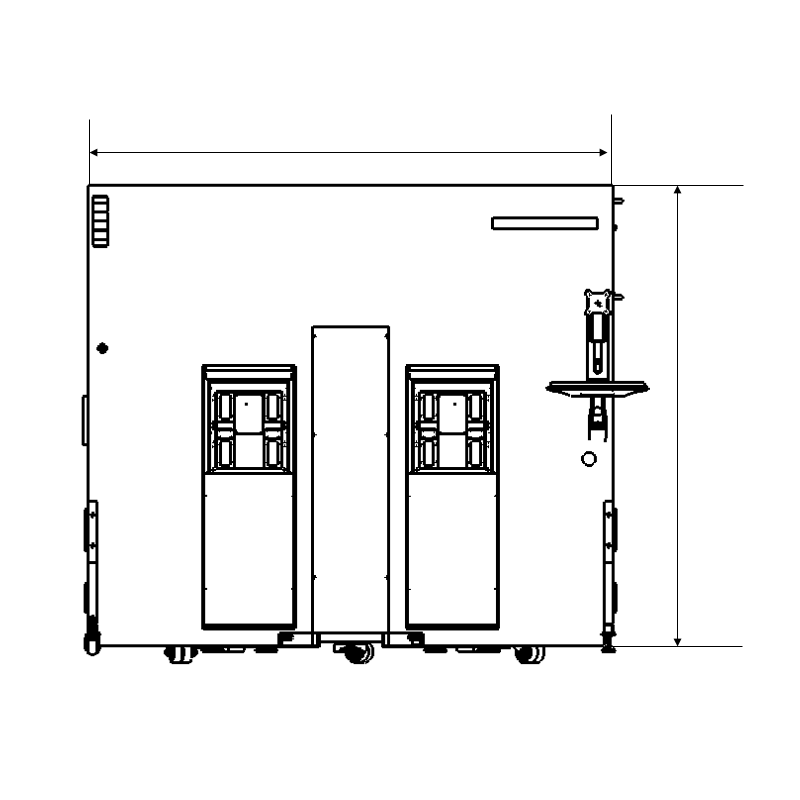

Front view

Specification

| Basic | Power Supply | AC 220V 50Hz 1500W | |

| CDA | 0.3-0.7MPa | ||

| Platform | 1100mm | ||

| Wafer Size | 300mm 200mm 150mm 100mm | ||

| Cleanliness | Class 1 | ||

| Base Vacuum | 5 x 10(−8) Torr | ||

| Leak Rate | <1 x 10(−9)std.cc/sec He | ||

| Robot | Model | HHVRD32 | |

| Range of Motion | R-axis | 1050mm | |

| Z-axis | 50mm 100mm 150mm | ||

| Maximum transfer speed | 1000mm/sec | ||

| Repeatability | R-axis、Z-axis | ± 0.05mm | |

| T-axis | 0.005° | ||

| VPA | Calibration Accuracy | Rotational Alignment Repeatability | 0.3° (3σ) |

| Centering Repeatability | 0.05mm | ||

| Initial Capture Range | +3.99mm | ||

| Alignment Period | 3.5-4.7sec | ||

| VCE | Key features | Detection of laminations or oblique plates | |

| Cassette Mapping Period | 20sec | ||